Add to Cart

Ferrite Strontium Powder As Raw Material To Produce Permanent Magnet Ferrite For Fan Motors W075C

What does Xinheng offer to customers?

Our company manufactures an-isotropic ceramic strontium ferrite magnet made by means of wet compression molding.

What's the feature of ceramic strontium ferrite magnet made by wet compression molding?

Composition - Contain strontium ferrite (SrFe12O19) as the primary magnetic material. Strontium ferrite has good magnetic properties and is inexpensive to produce.

Density - Have a high relative density of around 95% or more after sintering. This gives good mechanical strength.

An-isotropy - Exhibit strong magnetocrystalline an-isotropy due to their hexagonal crystal structure. This results in a preferred direction of magnetization along one axis.

Particle shape - The strontium ferrite powder used typically has a hexagonal platelet morphology which helps promote magnetic an-isotropy during molding and sintering.

Molding method - The powder is mixed with a liquid binder and compression molded into a dense green compact using high pressures. This orients the an-isotropic particles.

Firing process - The compact is then sintered at high temperature to develop density while preserving the induced magnetic anisotropy orientation from molding.

Remanence - Have a maximum magnetic flux density or remanence along the axis of anisotropy, but little/no remanence perpendicular to it.

Coercivity - Usually have medium to high coercivity depending on additives, density, and anisotropy level achieved.

What's the key advantages of ceramic strontium ferrite magnets made by wet compression molding?

Low cost - Strontium ferrite is inexpensive and the wet molding process is relatively simple. This makes them cheaper than rare-earth magnets.

High magnetic property-Even without heavy rare earth element additions, strontium ferrite magnets can achieve coercivities of 700-1000 kA/m, making them suitable for many applications.

Dimensional consistency - The compression molding process allows for close dimensional tolerances and uniform magnet shapes to be produced consistently.

Temperature stability - Strontium ferrite magnets have high Curie temperatures, typically around 450-470°C. They maintain good magnetic properties over a wide operating temperature range.

Resistance to corrosion - Being fully dense ceramic materials, they are not prone to corrosion like bonded magnets containing additives.

Mass production capability - The molding process is amenable to automated high-volume manufacturing of complex magnet geometries.

PHYSICAL PROPERTIES OF SINTERED FERRITE MAGNETS

| Units | Sintered Ferrite (Ceramic) | |

| Curie Temperature | ºC | 450 |

| Maximum Operating Temperature | ºC | 350 |

| Hardness | Hv | >530 |

| Density | g/cm3 | 4.8 – 5.0 |

| Relative recoil permeability | μrec | 1.05-1.1 |

| Temperature Coefficient Br | %/ºC | -0.18 |

| Temperature Coefficient iHc | %/ºC | 0.11-0.40 |

| Anti-Bending Strength | N/m2 | (0.5-0.9)×108 |

| Anti-Compressive Strength | N/m2 | ≥6.9×108 |

| Anti-Tensile Strength | N/m2 | (0.2-0.5)×108 |

| Specific Heat | J/kg·K | 600-900 |

| Resistivity | Q.cm | >104 |

What's the application of Xinheng's permanent ferrite magnets?

Xinheng mainly manufactures the following types of ceramic arc segment magnets:

How Xinheng fabricates its permanent strontium ferrite magnet?

FERRITE POWDER GRADE OF FAN MOTORS MAGNET

| 牌号 Grade | Br(mT) | Hcb(KA/m) | Hcj(KA/m) | (BH)max(KJ/m3) | ||||

| mT | Gs | KA/m | Oe | KA/m | Oe | KJ/m3 | MGOe | |

| Y30H-1 | 380-400 | 3800-4000 | 230-275 | 2890-3460 | 235-290 | 2950-3640 | 27.0-32.5 | 3.4-4.1 |

| Y33 | 410-430 | 4100-4300 | 220-250 | 2760-3140 | 225-255 | 2830-3200 | 31.5-35.0 | 3.9-4.4 |

| Y33H | 410-430 | 4100-4300 | 250-270 | 3140-3390 | 250-275 | 3140-3450 | 31.5-35.0 | 3.9-4.4 |

| Y33H-2 | 410-430 | 4100-4300 | 285-315 | 3580-3960 | 305-335 | 3830-4200 | 31.8-35.0 | 4.0-4.4 |

| Y35 | 430-450 | 4300-4500 | 215-239 | 2700-3000 | 217-241 | 2730-3030 | 33.1-38.2 | 4.1-4.8 |

| Y38 | 440-460 | 4400-4600 | 285-305 | 3580-3830 | 294-310 | 3690-3890 | 36.6-40.6 | 4.6-4.8 |

| Y40 | 440-460 | 4400-4600 | 330-354 | 4150-4450 | 340-360 | 4270-4520 | 37.6-41.8 | 4.7-5.2 |

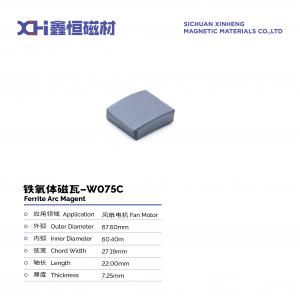

FAN MOTORS MAGNET SPECIFICATION TABLE

|

No. |

Item |

R |

r |

W |

L |

h |

Grade |

Application |

| 1 | W071 | 75 | 67.0 | 28.9 | 20.0 | 8.0 | Y30H-1 | Ceiling fan |

| 2 | W071A | 75 | 67.0 | 28.9 | 20.0 | 8.0 | Y33 | Ceiling fan |

| 3 | W077 | 87.5 | 79.5 | 65.8 | 19.5 | 7.9 | Y30H-1 | Ceiling fan |

| 4 | W089 | 76.2 | 76.2 | 44.0 | 25.0 | 10.0 | Y30H-1 | Ceiling fan |

| 5 | W101 | 87.5 | 79.5 | 37.0 | 19.5 | 8.0 | Y30H-1 | Ceiling fan |

| 6 | W102 | 56.75 | 48.25 | 38.0 | 25.0 | 8.5 | Y30H-1 | Ceiling fan |

| 7 | W112 | 87.5 | 79.5 | 35.0 | 20.0 | 8.0 | Y30H-1 | Ceiling fan |

| 8 | W130 | 87.5 | 79.5 | 30.5 | 20.0 | 8.0 | Y30H-1 | Ceiling fan |

| 9 | W3130B | 87.5 | 79.5 | 30.5 | 20.0 | 8.0 | Y33 | Ceiling fan |

| 10 | W115 | 29.5 | 21.5 | 14.5 | 38.0 | 8.6 | Y33H-2 | Floor fan |

| 11 | W4187 | 17.05 | 25.4 | 21.26 | 34.0 | 5.9 | Y33H-2 | Floor fan |

Introduction Of Fan Motor:

Permanent magnet ferrite is a kind of magnetic material with high permeability, high coercivity and high magnetic energy product, which is usually used to make fan rotors. Permanent magnet ferrite has the following effects on the fan rotor:

Providing a stable magnetic field: Permanent magnet ferrite has stable magnetic properties, which can provide a stable magnetic field on the fan rotor, thereby helping the fan achieve efficient speed and wind output.

Improve efficiency: The use of permanent magnet ferrite to make the rotor can improve the efficiency of the fan, because it has a higher permeability and magnetic energy product, can produce a stronger magnetic field inside the rotor, thereby improving the efficiency of the fan.

Energy saving and environmental protection: The fan rotor made of permanent magnet ferrite can generate a magnetic field without the need for an external power supply, thus saving energy and environmental protection, reducing dependence on external power, reducing energy consumption and environmental pollution.

To know more about Xinheng Magnets